Laboratory process testing and research and development of metallurgical technology

Laboratory establishment and technical training for laboratory technicians

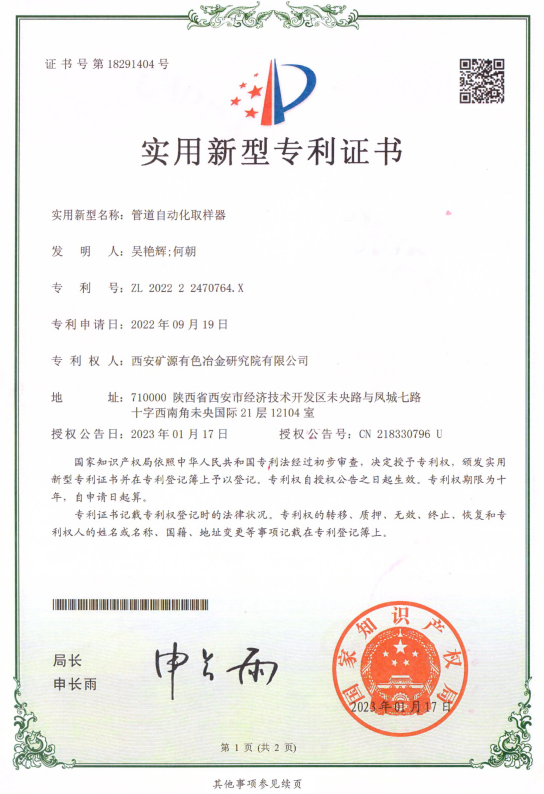

Our latest patent update

Our metallurgical technology research and development center was relocated to a new location in September 2022: Room 402, Building B, Chang'an University Science and Technology Park, No. 4555 Guangyuntan Avenue, Chanba Ecological Zone, Xi'an City.

In April 2022, our analysis and testing center was officially established, located at 4555 Guangyuntan Avenue, Chanba Ecological Zone, Xi'an, in the Chang'an University Science and Technology Park

In August 2020, Xi'an Kuangyuan Nonferrous Metallurgy Research Institute signed a contract with a certain Inner Mongolia Gold Mine Co., Ltd. for the construction of a gold mine beneficiation process flow test

Having over 60 types of ores

Mining and selection technology and experience

More than 10 experienced external experts

Involving majors such as mining, mineral processing, metallurgical and environmental protection

Having senior engineers

12 talents above

There are currently more than 50 professional and technical personnel,

Involved in majors such as geology, mining, selection, metallurgical and environmental protection

Xi'an Kuangyuan Nonferrous Metallurgical Research Institute Co., Ltd. has undertaken a beneficiation experimental research project for a fluorite mine in Inner Mongolia. The fluorite mine is a quartz calcite type fluorite mine, with fluorite grades of 20-30%, quartz 20-25%, and calcite of about 5% in the original ore, making it difficult to select fluorite mines.

Xi'an Kuangyuan Nonferrous Metallurgical Research Institute Co., Ltd. has undertaken a beneficiation experimental research project for a fluorite mine in Inner Mongolia. The fluorite mine is a quartz calcite type fluorite mine, with fluorite grades of 20-30%, quartz 20-25%, and calcite of about 5% in the original ore, making it difficult to select fluorite mines.

Xi'an Kuangyuan Nonferrous Metallurgical Research Institute Co., Ltd. has undertaken a beneficiation experimental research project for a fluorite mine in Inner Mongolia. The fluorite mine is a quartz calcite type fluorite mine, with fluorite grades of 20-30%, quartz 20-25%, and calcite of about 5% in the original ore, making it difficult to select fluorite mines.

Xi'an Kuangyuan Nonferrous Metallurgical Research Institute Co., Ltd. has undertaken a beneficiation experimental research project for a fluorite mine in Inner Mongolia. The fluorite mine is a quartz calcite type fluorite mine, with fluorite grades of 20-30%, quartz 20-25%, and calcite of about 5% in the original ore, making it difficult to select fluorite mines.